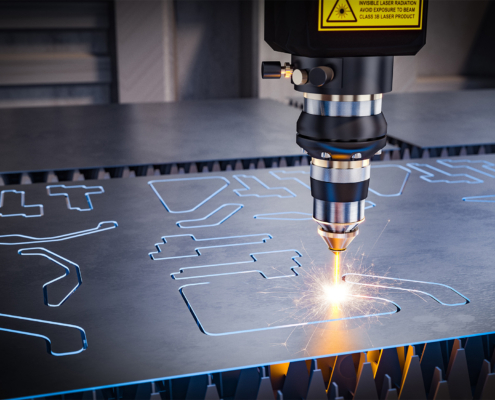

The Role of Robotics in Automated Cutting Systems

The manufacturing industry is undergoing a major transformation with the rise of artificial intelligence (AI) and robotics. Automated cutting systems, once limited to basic programming and repetitive tasks, are now leveraging AI-driven robotics to achieve higher precision, efficiency, and adaptability. As industries seek to optimize production, AI-powered robotics are becoming an essential component in modern automated cutting systems.