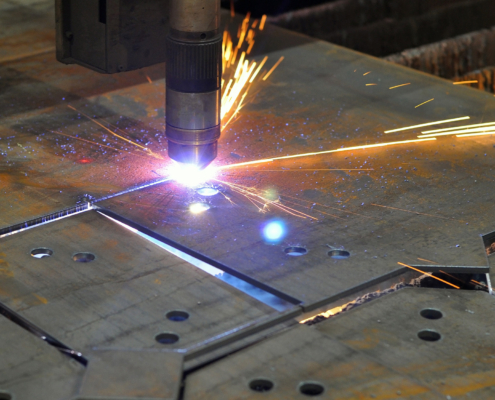

Automated cutting systems utilize computer-controlled technology to execute precise cutting operations with minimal human intervention. These systems integrate software, sensors, and robotic arms to perform tasks efficiently and accurately. They often work in tandem with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, enabling manufacturers to convert digital designs into flawless physical components.

These systems ensure consistency in every cut, eliminating manual errors that lead to material waste. Advanced CNC (Computer Numerical Control) systems and robotic automation allow for intricate cutting patterns, ensuring precision in even the most complex designs. Additionally, many modern systems feature artificial intelligence (AI)-driven optimizations, which can adjust cutting parameters in real time based on material properties and environmental conditions, leading to even greater efficiency and accuracy.