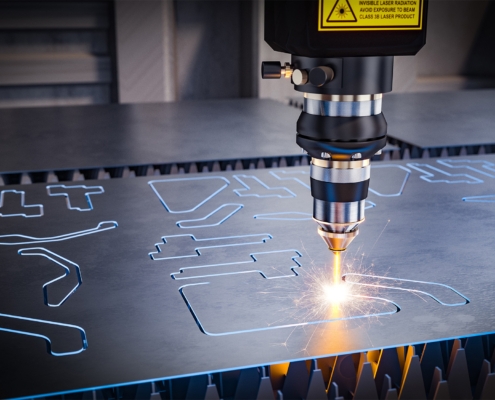

The journey of material handling robots began in the 1960s, with the introduction of the first industrial robots. These early machines were quite rudimentary, designed for simple tasks like picking and placing objects. Over the years, these robots have evolved significantly, becoming integral to manufacturing and distribution processes worldwide. Today, material handling robots are sophisticated systems equipped with advanced sensors, artificial intelligence, and the ability to handle a wide range of tasks with precision and efficiency.

The evolution of material handling robots has been marked by significant milestones. Initially, these robots were limited by their payload capacities and the types of tasks they could perform. However, as technology advanced, so did the capabilities of these robots. The development of more robust and versatile robotic arms, coupled with improvements in software packages, allowed for the automation of more complex material handling tasks. This progress opened the door to applications in diverse industries, ranging from automotive to food and beverage.

One of the key factors driving the evolution of material handling robots has been the growing need for efficiency and productivity in production facilities. As industries faced increasing competition, the demand for automation solutions that could reliably speed up production lines while maintaining or improving quality became paramount. Material handling robots emerged as a vital solution, capable of working tirelessly around the clock, thus significantly boosting production rates.