The advantages of robotic welding are vast and impactful. Arc welding robots, for instance, significantly boost production speed while maintaining a consistent weld quality. They are adaptable to various welding tasks, making them highly valuable in diverse manufacturing settings.

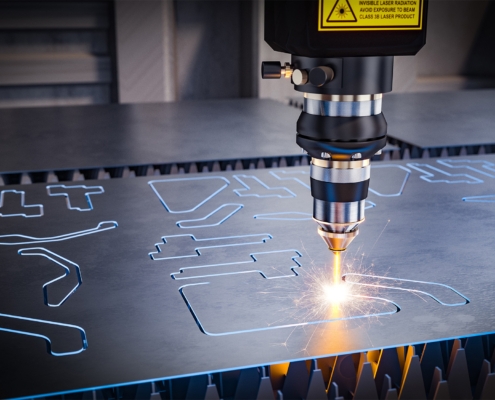

Resistance and laser welding robots offer unique benefits as well. Resistance welding robots excel in fast-paced, high-volume production environments like automotive manufacturing, ensuring quick and reliable joins. Laser welding robots, on the other hand, provide unparalleled precision and speed, ideal for applications requiring meticulous detail and minimal thermal distortion.

Across all types, robotic welding solutions enhance efficiency and quality assurance, translating into increased manufacturer productivity. The consistent output from robotic welders reduces the need for rework, saving time and resources. Moreover, integrating automated welding processes in manufacturing plants exemplifies a successful stride towards greater automation and innovation, promising enhanced customer success and industrial competitiveness.