Benefits of Automation Systems for Industrial Companies

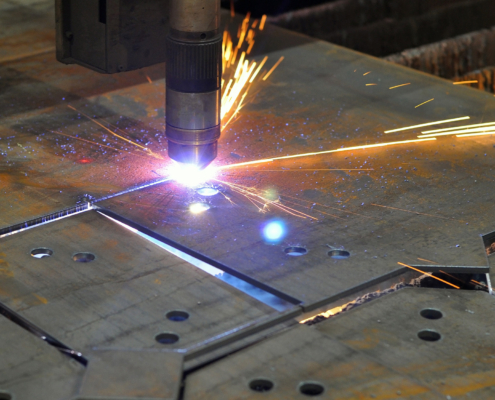

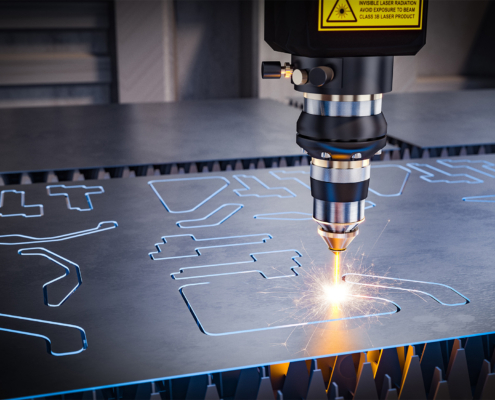

In the modern manufacturing landscape, industrial automationsystemsare a cornerstone for companies aiming to skyrocket their product output. By integrating advanced machinery and sophisticated control systems, industries are seizing unprecedented opportunities to refine their production processes. Discover how leading enterprises leverage the synergy between man and machine to transcend traditional production limitations, paving the way for a future where efficiency and precision reign supreme.